“We find that more and more companies are seeing the possibilities in robotic warehousing. In fact, you eliminate all the time spent on moving around in the warehouse and picking, which increases profitability,” says Nikolaj Bjørn Eriksen, CEO of Element Logic Denmark.

Largest investment ever

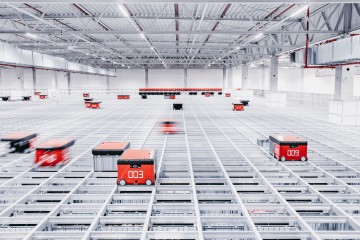

Prime Cargo’s installation is the largest investment in the company’s history. When the AutoStore system is fully operational, it will be able to process 20,000 orders a day from a warehouse with more than 500,000 articles. That makes up 50% more compared to the previous manual warehouse.

“Capacity and flexibility are the two major keywords for this installation. We have previously experienced bottlenecks during peak periods at our manual warehouse, which lowered our efficiency. With this AutoStore system, we can increase efficiency as well as capacity and at the same time make better use of the square meters”, says Morten Høilund, CEO of Prime Cargo.

Ready to be tested during Black Friday and Christmas season

Element Logic is a total supplier of the project, which in addition to the robotic AutoStore warehouse includes several other automation solutions – e.g. automatic box lifters and case closers.

“In addition to the robot warehouse itself, Prime Cargo has invested in automating the processes around the AutoStore system so that they can offer their customers a strong, comprehensive logistics solution,” says Nikolaj Bjørn Eriksen.

Initially, Prime Cargo’s facilities will be tested during this year’s Black Friday and subsequent Christmas sales.

Facts

- Holds a total of 88,000 bins, 16 stories high

- The goods are handled via 49 robots

- 9 conveyor ports for inbound

- 8 carousel ports for picking