Customer demand for same-day or next-day deliveries and click-and-collect options are compelling companies to adjust their omnichannel distribution strategy. To shorten the delivery time, some European retailers, notably those in the grocery market, are launching micro fulfillment centers (MFCs)

To find out more about micro fulfillment centers and the other trends shaping intralogistics, download our whitepaper: Three emerging trends shaping intralogistics

Operating as small warehouses, companies can install MFCs nearly anywhere closer to customers. They can be inside a physical store, in an adjacent building or inside a ‘dark store’ where inventory and products are staged, but only employees have access. In addition to flexibility, a micro fulfillment solution provides predictability and fast deliveries to customers visiting the store and those who prefer to shop online. It also allows for better inventory control and tracking, quicker and easier returns, and lower transportation costs.

The dark store concept combined with the regular storefront where a dedicated space at the back operates as a micro fulfillment center, will shape the future of logistics. While micro fulfillment is undoubtedly an innovative trend, many companies still rely on manual labor, despite the associated drop in productivity. There’s a limit to the number of products human labor can pick per hour, and a warehouse only has a certain amount of shelf space. Automating the micro fulfillment process, can drastically improve efficiency and reduce operating costs.

The most significant difference between a manually operated and an automated micro fulfillment center is storage density. Keeping hundreds or thousands of products in stock in a small space can be overwhelming and challenging to control. Investing in an automated modular solution increases storage capacity significantly. This makes the apparel sector, for example, a perfect candidate for micro fulfillment.

Automation in action

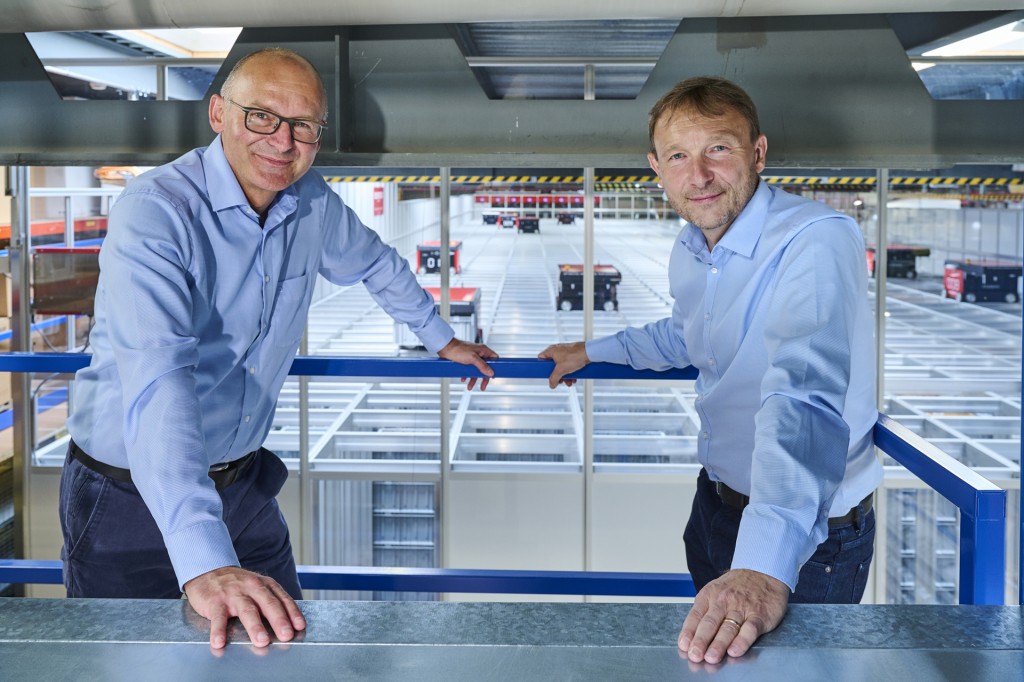

One company that achieved great success with automation is Peterhans, a Swiss-based company that supplies tools, fittings, machines, and materials to contractors in the building industry. They also specialize in the assembly and mounting of hardware for industrial and commercial customers. Using a combination of a regular storefront and an extended warehouse in the back, they invested in an AutoStore system from Element Logic in 2018.

The system uses AutoStore 220mm bins at eight levels totaling 11,650 bins. The grid covers 400m2, which occupies only ten percent of the warehouse’s total floor space, making future expansion possible. The system also supports employees in their daily work, which is now much less labor-intensive since they no longer have to walk long distances and lift heavy goods.

By automating, Peterhans improved storage capacity (they keep 500,000 items in their online store alone) and increased warehouse efficiency. Immediately after installation, the system made it possible to meet same-day delivery expectations and ensured a shorter waiting period at the pick-up counters inside the store. A customer order takes less than two minutes to arrive at the sales counter. Since the ports are located next to the sales counters, customers can watch their orders being processed on-site, making for a unique and rewarding customer experience.

Using micro fulfillment to increase customer satisfaction

Businesses know that an excellent customer journey is a competitive advantage. Micro fulfillment adds considerable customer value – order online and pick up locally to save on delivery fees and benefit from same day convenient collection.

Therefore, as demand for same-day delivery increases and consumers get used to the comfort of fast deliveries, more and more industries are likely to make micro fulfilment part of their omnichannel offering.

To find out more about micro fulfillment centers and the other trends shaping intralogistics, download our whitepaper: Three emerging trends shaping intralogistics