FusionPort™

FusionPort™ – Technical Specifications

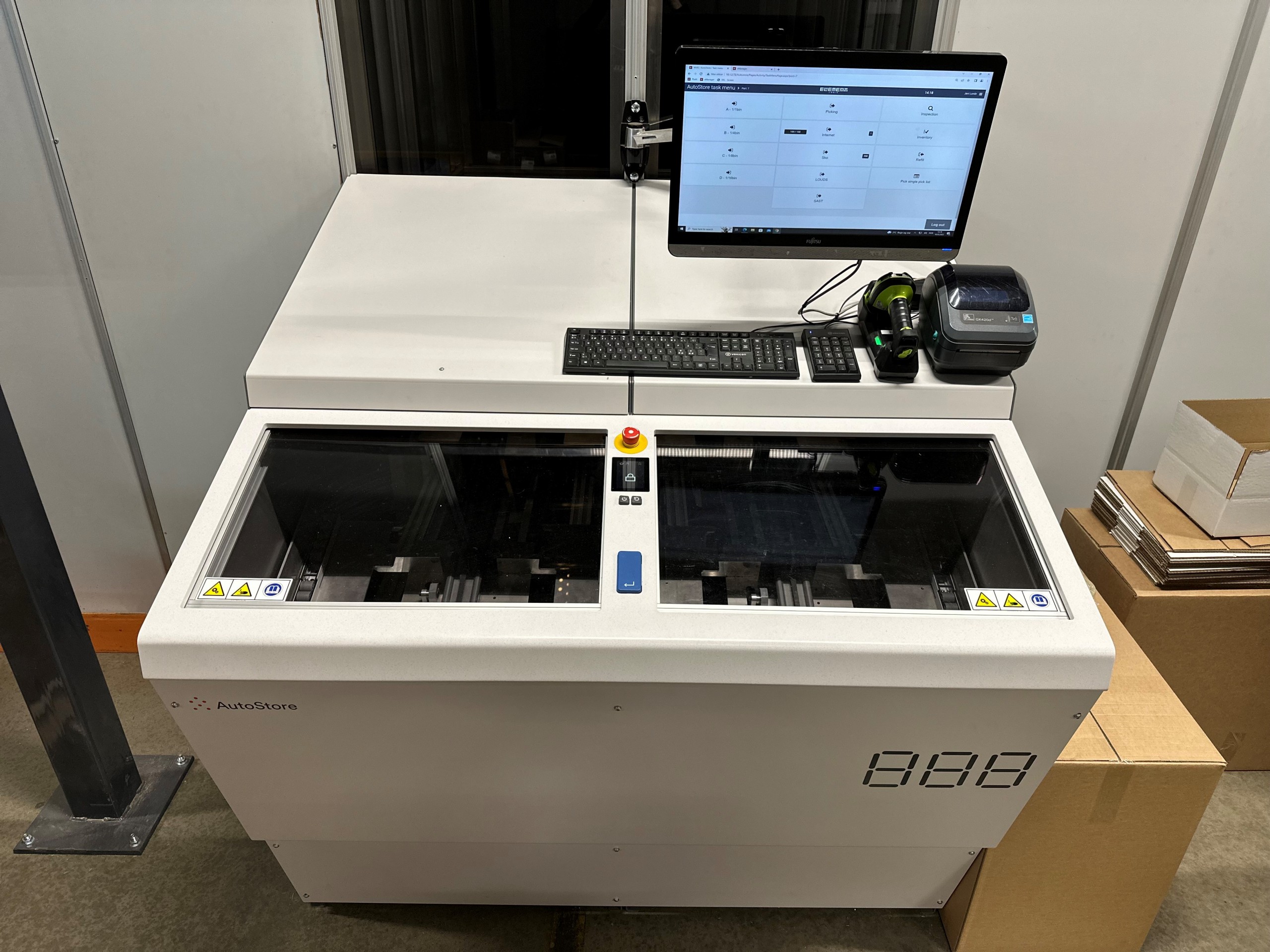

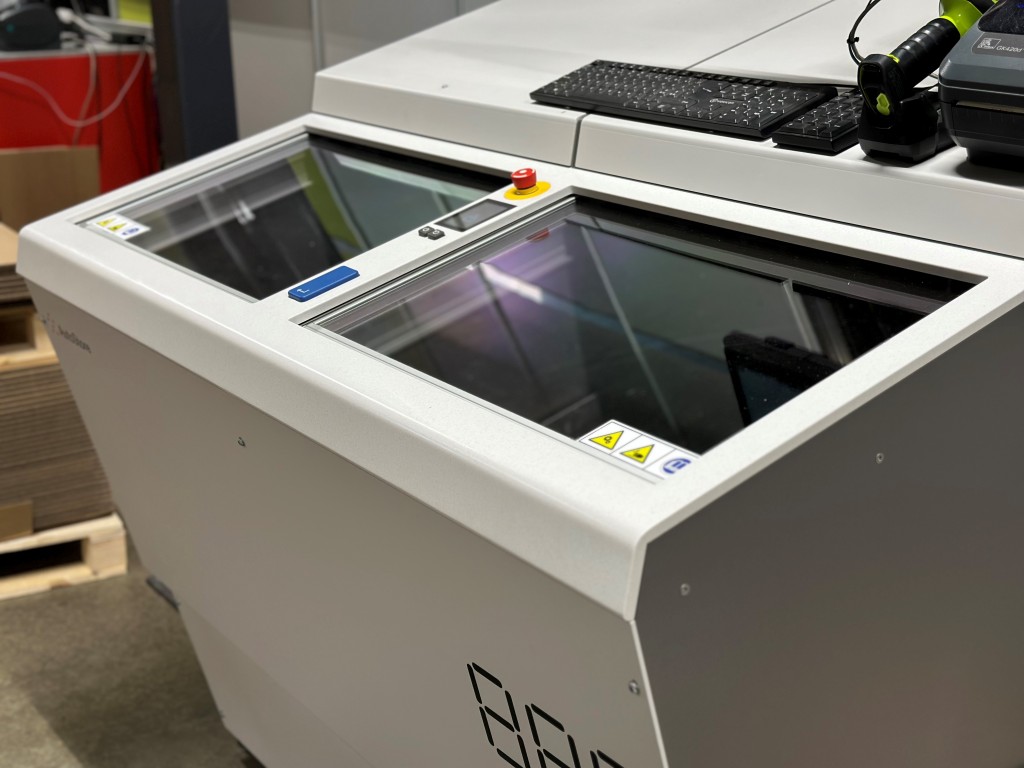

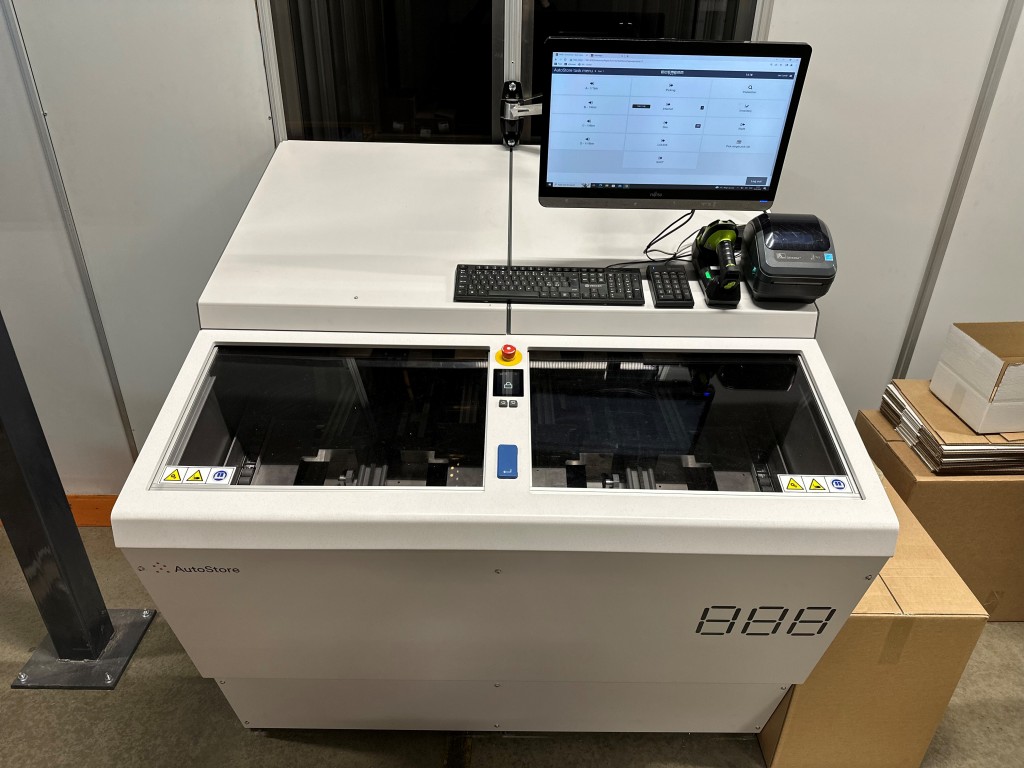

- Two source bin openings with 15° tilt

Throughput 2×275 = 550 bins/h - Integrated visual picking aids

- User screen interface

- Safety hatch

The new offerings from AutoStore are built with three key points in mind: safety, ergonomics, and operator well-being. Additionally, the new ports also increase the overall versatility with considerations for robotic piece picking, more complex workflows, higher throughputs, and productivity features to boost accuracy and efficiency. As a key partner, we’ve been testing the FusionPort with one of our customers, XXL, for the past year.

The new port offerings will help logistic operations attract and retain associates to reduce turnover and increase productivity. The FusionPort™ introduces several key associate benefits with retention and associate satisfaction in mind.

A 15° forward tilt of the port/workstation to decrease the physical strain on associates. The tilted work area reduces the need for reach required for associates to pick from the back of a bin and gives greater visibility of all locations in that bin.

A Safety hatch to cover the workstation while bins are being exchanged. This is a sliding plexiglass-style door that will open once an item is ready to be picked and closed once that transaction is complete. Other ports have safety features included as well, but the hatch provides a more comprehensive safety measure to help reduce workplace accidents and ensure the safety of the operator.

Integrated pick-to-light system is designed to help guide the operator to the correct pick as a light will illuminate the correct bin location for the operator to pick from. Pick-to-light is designed to simplify the operator workflow, decrease stress while operating the port, reduce errors, and simplify training. The FusionPorts™ pick-to-light minimizes the repetitive need to look at or interact with the port, furthering the ergonomic benefits.

The FusionPort was installed into an existing system at our customer XXL and is being tested for batch picking multiple order lines during each bin presentation. While testing the FusionPort XXL achieved a 50% improvement in operator efficiency, with peak throughputs close to 400 bins/hr.

"For us at XXL, we have experienced several advantages with the FusionPort. Compared to other ports from AutoStore, it is more ergonomic due to the height of the port and that it is tilted. The Fusionport is without a doubt more efficient than other ports and more user-friendly with the new features. If I were to give a recommendation to others on which port to invest in, it would be this one."

From a productivity and systems integration standpoint, the FusionPort™ is designed to be the most versatile port to date. The two bin openings allow for more automated picking and improved workflows; a robotic picking arm can alternate which bin it is picking from. It is possible to prepare one bin while the second bin is being picked from or utilize both port openings in a customized combination. This bin flexibility, added to the 15° tilt, creates the most ergonomic and optimized workstation available from AutoStore.

Order consolidation at AutoStore ports is nothing new. What is unique about the FusionPort Staging™ is that it combines order consolidation and staging in a single port. FusionPort Staging™ allows businesses to streamline operations and reduce real estate costs by decreasing the space required for staging. Companies can now pick from a main source bin and place the items into a target bin directly to the left or right of the main picking bin. This target bin is then taken back into AutoStore to be stored and staged until it is time to ship out. It is now possible to store consolidated orders within AutoStore in a dust free, secure, and if needed, in a temperature-controlled area for applications like e-grocery or micro fulfillment centers.