There were several reasons why Kitron chose to automate with Element Logic, and one of them was that the industry they operate in is very competitive and characterized by a lot of outsourcing abroad for cheaper labour.

“Due to the ability and willingness to automate our processes, we are now in a situation where we are hiring more employees”– Tone Helle, Kitron

– The fact that we are competitive means that we staff up, not down. The employees have been enthusiastic about automation from the very beginning and understand that it is necessary to be able to continue operating from Norway, says Tone Helle, Production Planning Manager i Kitron.

Automated solution produces and distributes electronics.

Kitron is a contract manufacturer of electronics for the professional market. The history of the Norwegian company goes back to the 1960s in the Arendal area south of Norway. Since then, they have experienced several mergers and changes in the company. Until 2015, Kitron had two production sites in the Arendal area, but when the renting contract expired on one of the sites, they chose to move all operations to the remaining production site.

– This warehouse was too small for us and we had to optimize the warehouse solution to get enough space. After a couple of internal rounds of discussions, the natural choice naturally was AutoStore from Element Logic, says Helle.

Developed tailor-made AutoStore solution.

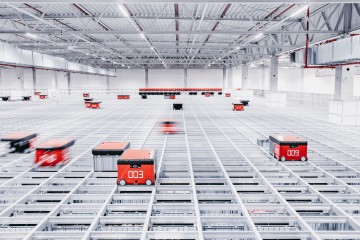

The components Kitron uses to produce electronics are getting smaller and smaller in line with technological development. Kitron needed AutoStore to be able to efficiently retrieve small components for production and put the superfluous parts back in stock. The solution became a custom AutoStore system where some of the boxes are designed to be divided into as many as 30 locations.

– Kitron was our first customer in need of picking for production and returning the remaining parts in the storage bins. We designed a new solution with custom-built dividers in the bins that simplified the process and significantly reduced storage space. The effective solution picks between 2,000 and 2,500 transactions daily, Arnold H. Nielsen, Key Account Manager at Element Logic Norway, explains.

We designed a new solution with custom-built dividers in the bins that simplified the process and significantly reduced storage space.

– As this was the first time such an integration was carried out, it required some extra resources to get it in operation. As an AutoStore specialist, this gave us valuable insight that we have benefited from since, Nielsen explains.

Want to read more about the whole process of AutoStore projects with Element Logic?

Read more here.

From 6300 to 7000 storage bins

Service technicians from Element Logic perform three regular service intervals a year at Kitron. In addition, Kitron can easily contact the experts in the support team whenever needed during the year.

– We experience that Element Logic responds quickly when challenges arise or when software upgrades are needed, says Helle and adds:

– We are very pleased with the efficiency our AutoStore solution has given us, and we have not had downtime since starting six years ago.

Kitron has increased the number of bins from 6,300 to 7,000 bins in recent years, but still has good opportunities for further expansions when the time is right.

– The best thing about AutoStore is that it is reliable, flexible, and easy to scale. As soon as the design is clarified, integration and installation go very smoothly, Helle concludes.

Facts and figures

- Warehouse of 700 m2

- 350 employees

- 7 robots

- AutoStore system of 187 m2

- 7000 AutoStore bins

- 1 Carousel ports

- 2 Conveyor ports

- Between 2000 og 2500 transactions picked daily from AutoStore