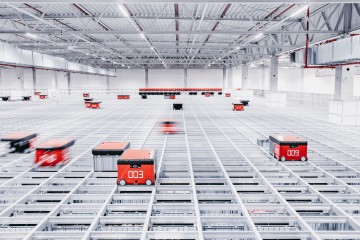

In order to further strengthen its competitiveness, Proshop invested in a 1 080 m2 big AutoStore installation to boost the efficiency and profitability of the company in a very price-competitive market.

A fleet of 40 AutoStore robots now controls 80 percent of all the material handling. As a result, they gained 75 percent of inventory space, compared to their previous manual warehouse.

Annual growth of 20 percent in the past years

The easy scalability of an AutoStore system was the basis for future growth for Proshop, as they now are able to expand the number of robots, bins, or ports in a quick and easy way, based on growth rates and needs.

Proshop’s warehouse system also has a sorter solution, pick and pack stations and finally external inbound stations. Overall, the complete automated warehouse makes it possible for Proshop to manually touch the articles no more than 2 times, from the time the article arrives, is stored, picked, packed and ready for distribution.

In comparison, Proshop previously touched the article 4-5 times in their manual process. Today they have the fastest and most stable delivery from warehouse to customer.

Ready for the next step?

Find out how Element Logic can optimize your warehouse performance