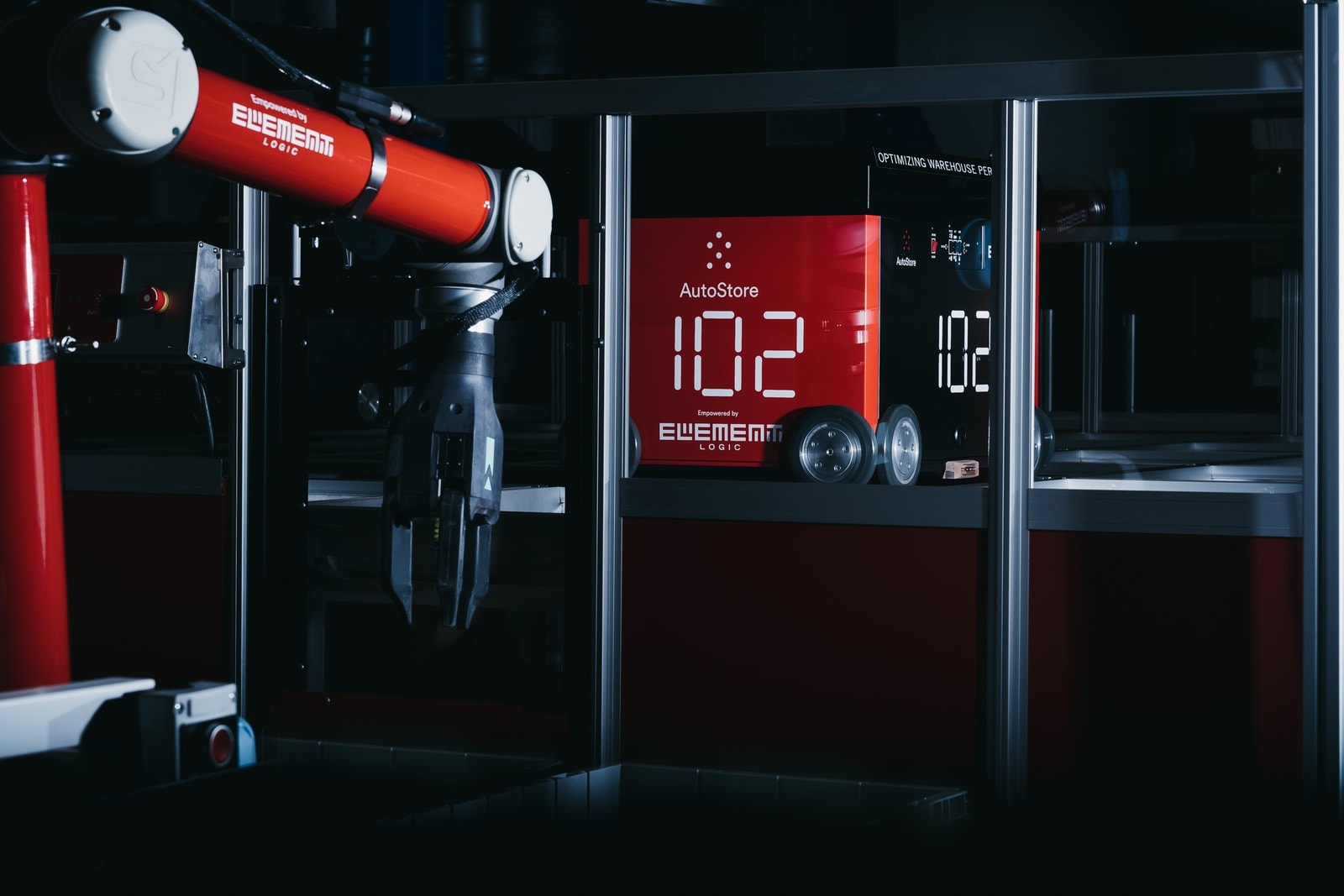

The robotic piece-picking solution by Element Logic combines award-winning technology from RightHand Robotics with Element Logic software and AutoStore. The solution integrates with any warehouse management software, enabling customers to decrease operational cost and boost overall profit.

PODCAST: Listen to our CTO’s perspectives on the future of robotics (from 28:20 min)

Range, Rate, and Reliability

RHR’s technology excels at the 3Rs of robotic piece-picking: Range, Rate, and Reliability. The technology is able to pick and place a wide range of items and fulfil orders at high speeds while ensuring that customers consistently receive what they ordered. The system uses vision, machine learning, and an advanced multi-function gripper with gripping fingers and a suction cup that can be used independently or in tandem with humans at the same picking station for maximum flexibility.

“The Element Team’s expertise in warehouse automation has made the project run smoothly, and RHR is excited to be working together to connect robotic picking with customers’ operations,” said Leif Jentoft, co-founder of RightHand Robotics. “With proven reliability and millions of picks, the technology provides an obvious advantage in today’s environment of shrinking labour and increasing customer pressure for supply chain performance”.

Ready

The robotic piece-picking solution by Element Logic will help customers advance in their markets and is ideal for picking-related warehouse tasks.

Element Logic offers Design and Consulting services to ensure that customers know how this solution can work for them. This includes a pickability assessment where customers have the option to see for themselves how well the robotic piece-picking solution picks and places their SKUs, followed by a detailed report with recommendations for optimal use tailored to their specific needs.

Extensive and successful testing

Element Logic, together with RHR, went through rigorous testing to ensure that the product was ready for launch. First there was extensive testing in the lab at Element Logic’s headquarters. Later on: the big question – would it work in a live production environment?

As an existing Element Logic customer, electrical wholesaler Onninen’s warehouse was the perfect test location for the new robot. It worked flawlessly with the software and fit right in with the AutoStore robots, producing impressive results.

“Everything went perfectly. It’s obvious this robot arm can help us with efficiency, quality, and unfavourable working hours. I think this is the future of logistics, no doubt about it”, says Thomas Fosstveit, operations Manager at the Onninen.

“After a long test phase to ensure that our robotic piece-picking solution will produce profitable results for our customers, we are now ready to launch our collaborative robotic piece-picking solution. Our solution is ready to run with any warehouse management software to optimize warehouse performance. The interface is intuitive, reducing the need for training,” says Steinar Overbeck Cook, Chief Technology Officer (CTO) at Element Logic.