How to maximise small business performance with automated warehouse solutions

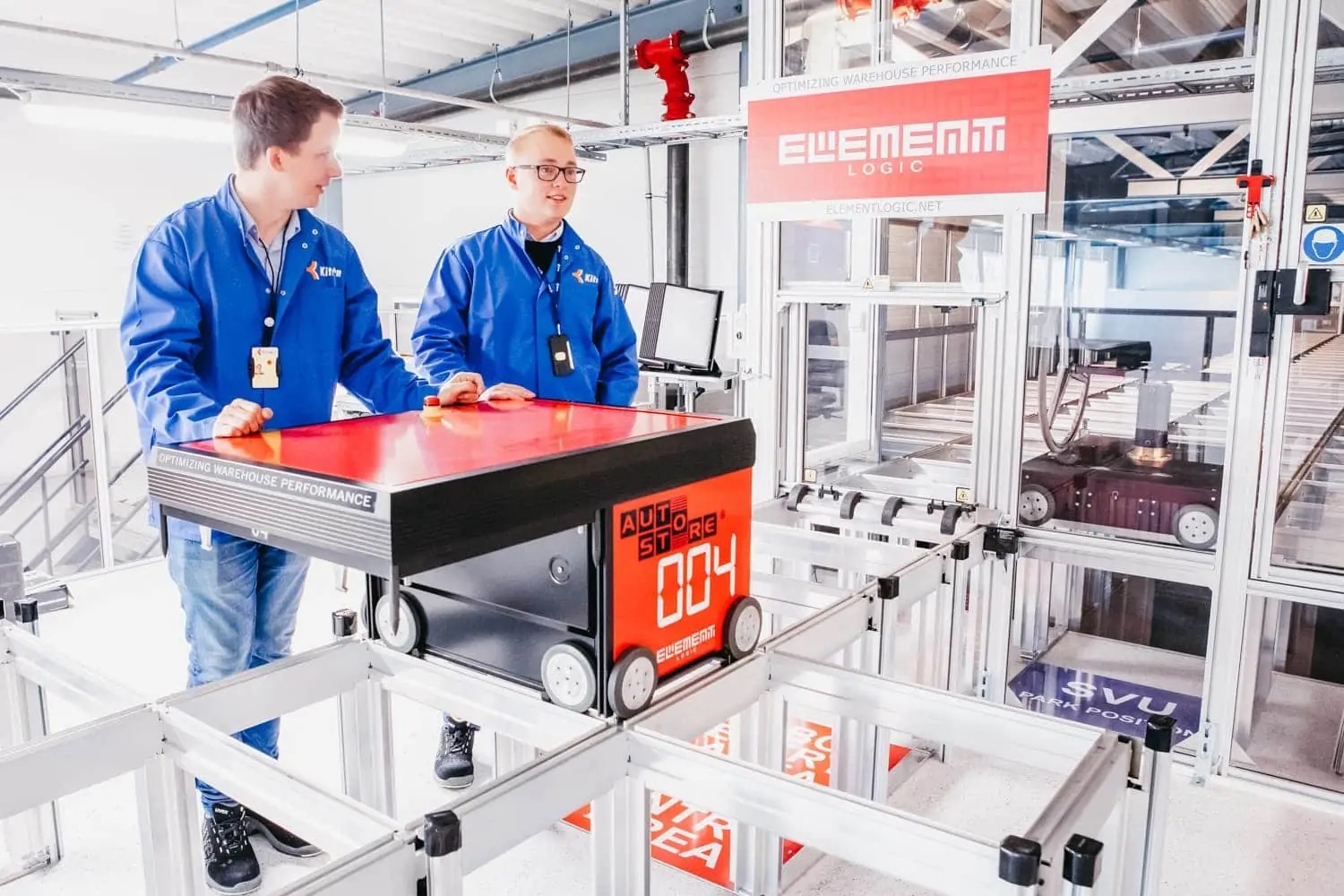

This article explains how Element Logic enhances operational efficiency for warehouses of every size - across industries.

“Though warehouse automation solutions require a notable upfront investment, the expenses related to warehouse expansion, error corrections, and loss of control can be equally taxing,” says Arnold H. Nielsen, Key Account Manager at Element Logic Norway. With nearly four decades of experience, Element Logic has provided AutoStore solutions to a vast and diverse range of industries, benefiting countless customers. These include retail, third-party logistics (3PL), apparel and sports, grocery, and pharmacy.

“We have catered to a variety of needs, including for small warehouses. One of our most compact solutions features approximately 1,500 bins, three AutoStore robots, and two operator stations. On the larger scale, Element Logic has deployed solutions boasting several hundred thousand bins, hundreds of robots, and up to a hundred operator stations,” adds Nielsen.

One of the smallest solutions we have delivered consists of about 1,500 bins, three AutoStore robots, and two operator stations. In addition, Element Logic has helped small businesses worldwide in their automation journey by delivering small solutions. German company Greendonkey has a dense warehouse of just under 2,300 bins, 6 robots, and three carousel ports.

In contrast, Element Logic has delivered solutions with over a million bins, over a thousand robots, and hundreds of operator ports globally. Boozt, the largest online department store in the Nordics, is home to the world’s most extensive AutoStore solution. The system contains 1,243 robots, over 1 million bins, and more than 300 ports. The fastest time in which an order was ready for distribution upon being received was 49 seconds.

Industry insights: Enhancing security and space efficiency

Companies manufacturing and supplying systems and components for diverse industries typically maintain high-value inventories. This means that control is extra important.

Jotron, a Norwegian company, specialised in the development and production of communication systems for professional applications in the air, on land, and at sea. Implementing an automated warehouse solution from Element Logic has made warehouse operations a distinct technological priority within the company.

“Jotron’s solution, encompassing a little over 1,500 bins, is among the smaller setups but perfectly illustrates the paramount importance of control. Given the pricey components it produces and dispatches, an AutoStore solution ensures that specific orders are required to access any part of the inventory, adding an extra layer of security,” says Nielsen.

If the warehouse had consisted of small goods racks, it would have occupied roughly four to five times more space.

Geir Ødegaard, Logistics Manager at Jotron, is full of praise for the solution provided by Element Logic:

“We’ve had nothing but positive experiences with our automated warehouse. It ensures optimal control and efficient management of storage and retrieval. Our operators appreciate that items are now delivered straight to them, removing the need to wander about looking for them.”

Learn more about our solutions and services.

Retail insights: Boosting productivity and maximising space utilisation

Space efficiency was the top priority when Viktoria, a provider of safety gear and work attire, looked to expand its warehouse in Drammen, Norway. To integrate as much of its production and storage as possible, the company took an unconventional route: purchasing a car workshop neighbouring its current print shop.

In the former car workshop, Viktoria has allocated a portion of space to an AutoStore solution from Element Logic, while the remaining space serves as a store.

“Within this setup, we successfully incorporated 3,200 bins, establishing a streamlined warehouse operation where the AutoStore robots retrieve the items,” Nielsen says.

Efficiency and innovation were also at the forefront when Alza.cz dedicated over 40 million euros to develop its newest logistics centre in Chrášťany, near Prague.

“With this progress, we can offer express deliveries to our customers, and orders can be packed and dispatched within a few minutes,” says Vice Chairman of the Board at Alza, Thomas Havryluk.

This represents the company’s most substantial investment to date. Beyond adding an additional 15,000 m2 to its existing space, Alza has incorporated AutoStore technology from Element Logic. This integration promises to enhance warehouse operations and reduce delivery time.

Third-party logistics insights: Streamlining adaptability and accelerating product dispatch

Accelerating the movement of goods is a compelling reason for third-party logistics providers to prioritise automation. AssistCo distributes brands like Hummel, CEP, Ball Launcher, and Assist to the Norwegian sports market. The company also manufactures its own brand, Assist, at its Rjukan facility.

“With close to 7,700 bins, AssistCo may not rank among our smaller clients, yet its facility is still on the compact side. It has strategically designed their AutoStore solution to be visible throughout the building. Not only does it offer a unique view of the robots in action from the office spaces, but it’s also highly functional. The structure is aptly designed for an AutoStore setup, enhancing both storage density and the speed at which products are dispatched from the warehouse,” says Nielsen.

“Flexibility is at the core of our offerings to all clients. Given sufficient space, our systems can easily scale or be transitioned to new locations for expanded warehousing needs. No matter the scale of a company’s expansion, we are equipped to customise warehouse automation to meet those demands.”

See how more of our clients have benefitted from automated warehouse solutions.

Boost ROI: Warehouse automation for enhanced profitability and efficiency

“Anticipating your needs by investing in Element Logic’s warehouse automation ahead of time is the strategic approach,” recommends Niklas Poulsen, Sales Manager at Element Logic.

“Many companies initially feel they are too small for warehouse automation to be cost-effective. Yet, once presented with the ROI analysis, their perspective often changes.”

Since Element Logic was established in 1985, the shortest payback period for an automated warehouse has been less than a year, and the longest has been around six years. We have discovered three key factors influencing warehouse automation ROI:

- Number of employees

- Lower rental costs

- Growth

Ready to discover the power of AutoStore for your small business? Contact our experts to learn more today.